Hi Kung fu,

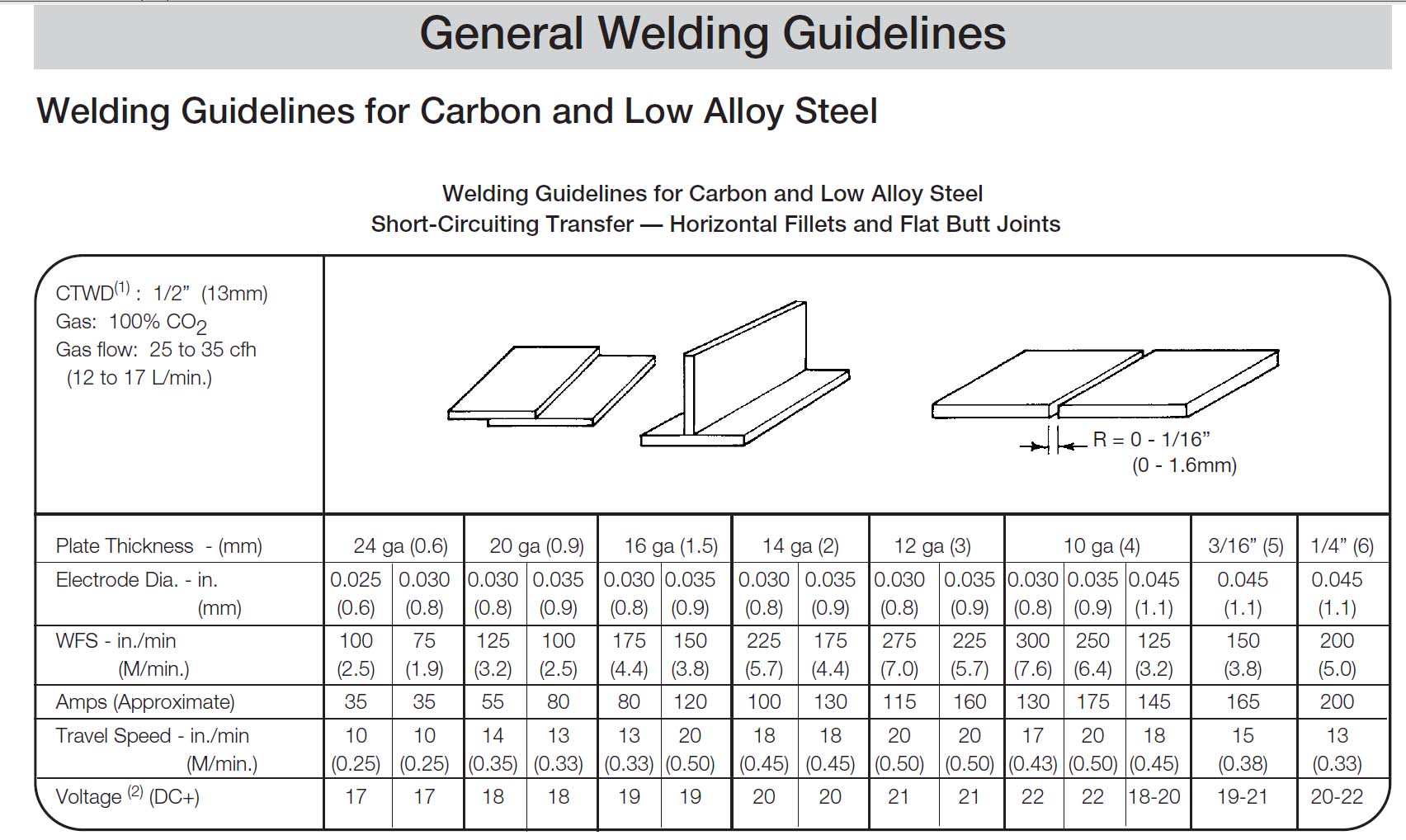

These charts are just starting points/rough settings to get your machine set somewhere fairly close, and then you will most likey have to fine tune the machine. It's just a place to start, that's all. While you are welding, so will be able to see what the puddle needs....more WFS or more voltage. There are only two knobs when wire welding that matter. Voltage and WFS(wire feed speed)

If the sparks are flying all over and you have spatter the size of the welding wire or larger, you have one of two situations:

Too much WFS for the voltage setting, or too little voltage for the WFS setting.

If the arc burns back up inside the tip, you have one of two situations:

Too much voltage for the WFS setting, or too little WFS for the voltage setting.

EDIT

BTW, the one thing that MUST remain constant is the ESO(electrical stick out)

EDIT#2 In the chart they call it CTWD(contact tip to work distance), this is measured from the end of the contact tip where the wire exits to the work. If this does not remain constant, you will chase your machine settings all day and never figure out what is going on.

it's all good Milton

it's all good Milton