Well Larry, That's going to be not so easy to do with your credibility so, let's see if we can come up with a compromise agreement and @ the very least, agree that just because we may disagree, we'll still respect each others opinion on this topic... I guess I'll start with this:

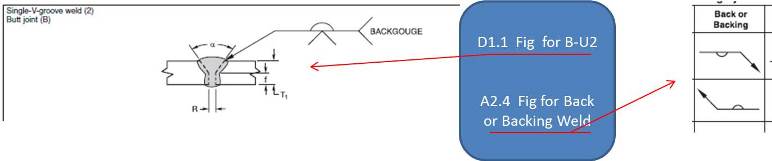

1) A2.4 states this in 4.7, page 25 for Back and Backing Welds:

"

4.7.1 General. The back and backing weld symbols are identical. The sequence of welding determines which designation applies.

The back weld is made after the groove weld, and the backing weld is made before the groove weld (see 4.7.2 and 4.7.30)

4.7.2 Back Weld Symbol. The back weld symbol is placed on the side of the reference line opposite a groove weld symbol. When a single reference line is used, "back weld"

shall be specified in the tail of the welding symbol. Alternately, if multiple reference lines are used, the back weld symbol shall be placed on a reference line

subsequent to the reference line specifying the groove weld [see Figure 27(A)].

4.7.3 Backing Weld Symbol. The backing weld symbol is placed on the side of the reference line opposite a groove weld symbol. When a single reference line is used, "backing weld" shall be specified in the tail of the welding symbol. Alternately, if multiple reference lines are used, the backing weld symbol shall be placed on a reference line prior to the reference line specifying a groove weld [see 27 (B and C)]."

2) Now let's go to page 27:

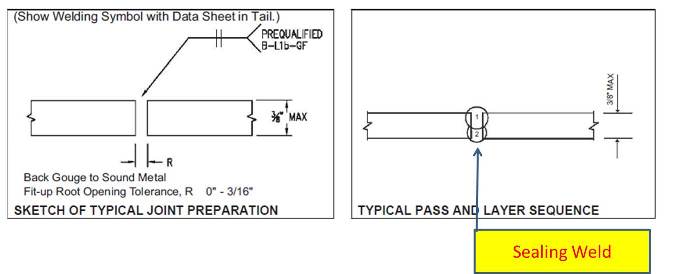

"4.11 Groove Welds with Backgouging. A joint requiring complete joint penetration involving backgouging may be specified using a single or multiple reference line welding symbol (see Figure 30).

The welding symbol shall include a reference to backgouging in the tail and (1) in the case of asymmetrical double-groove welds welds must show depth of bevel from each side (see Figure 28(A), together with groove angles and root opening, or (2) in the case of single groove welds or symmetrical double-groove welds, need not include except the weld symbols [see 4.2.2 and Figure 30 (B and C)], with groove angles and root opening."

AWS 3.0:2001 page 4,

3)

"backing weld. backing in the form of a weld. see Figure 24(D)."

4)

"back weld. A weld made at the

back of a single groove weld. See Figure 24(C)."

There is a difference and yet according to A3.0:2001, the definition of the term backing goes like this:

5)

"backing. A material or device placed on the backside of a joint adjacent to the joint root, or at both sides of a joint in electroslag and electrogas welding"

(These two welding processes should have been written in Parentheses(sis) to avoid confusion)", to support and shield molten weld metal. The material may be partially fused or remain unfused during welding and may be metal or nonmetal. see Figure 8(D), 12 and, 37."

And finally, let's look at the definition of backgouging according to AWS 3.0:2001.

6)

backgouging. The removal of weld metal and base metal from the weld root side of a welded joint to facilitate complete fusion and complete joint penetration upon subsequent welding from that side."

When you combine everything written in all of these definitions according to AWS 3.0:2001 and A2.4, I come to the overall conclusion that although it is not clearly written to which is the correct sequence if any, for a BU-2 joint in AWS D1.1, I see the words

"Sequence and Subsequent" stick out to help me determine that the prepared side shall be welded first followed by backgouging the weld root side of the joint in order to deposit a back weld after the backgouging and cleaning by grinding of the completed backgouge operation and is finished in order to complete this BU-2 CJP joint.

Respectfully,

Henry

I'm done here.

I'm done here.

And now that I'm finally receiving the correct amount of Oxygen to help me think much more clearly these days, I'm experiencing a renewed sense of clarity with everything and everyone and for that I am truly grateful.

And now that I'm finally receiving the correct amount of Oxygen to help me think much more clearly these days, I'm experiencing a renewed sense of clarity with everything and everyone and for that I am truly grateful.