Shawn,

First, it isn't for 'cosmetics'. It is for strength and distribution of forces/stresses.

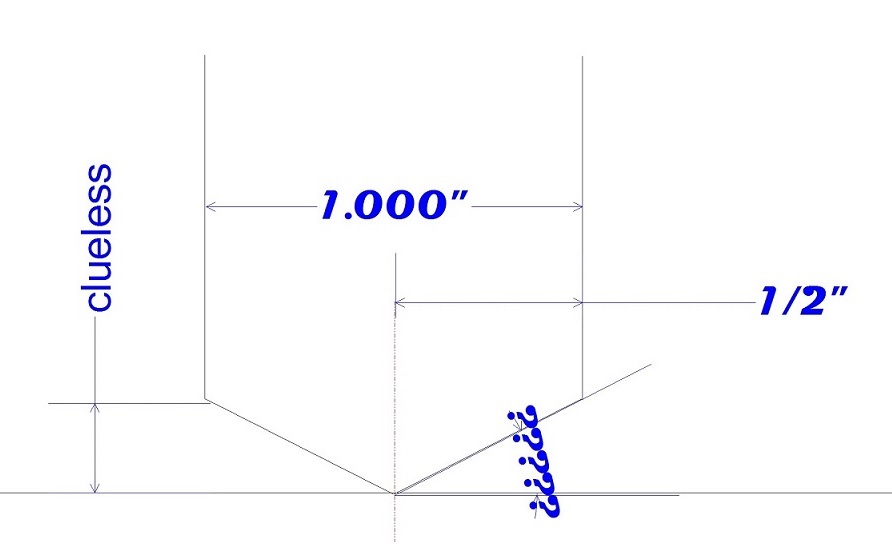

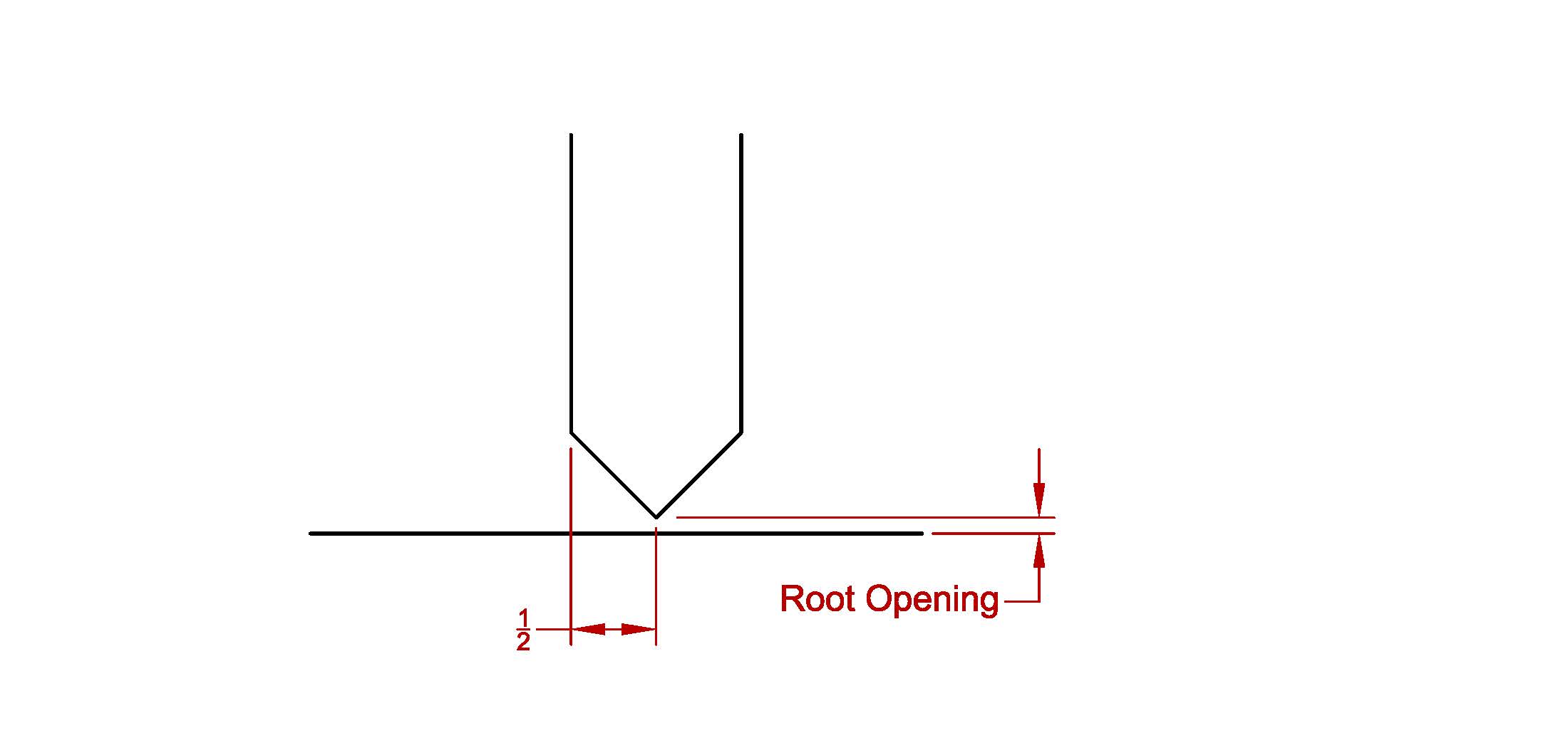

Second, you need to look at D1.1 Clause 3. Figure 3.4 TC-U5b.

Now, don't ask me why I'm feeling so generous, I must like you

. So, the root opening can be from '0' to 3/16" and the bevel angle can be from 40-55°. That is for SMAW with a double bevel.

There are some other figures that could apply, but they are all the same for opening and bevel angle so that should be close enough for your usage.

Now, at a 45° bevel, if it is 1/2" deep that means it will be 1/2" 'high' (the dimension up from the other plate or edge of the plate with the bevel, your question/clueless dimension).

That is why Al said you will need to go deeper on the backgouge to get to clean material. With the Z-loss factor you will only get about 3/8" deep with your first weld with SMAW. Even at an angle that would widen it more you won't get all the way and you add more heat, stress, and other negatives into the joint besides more weld metal, time, and cost.

Hope that helps.

He Is In Control, Have a Great Day, Brent

. So, the root opening can be from '0' to 3/16" and the bevel angle can be from 40-55°. That is for SMAW with a double bevel.

. So, the root opening can be from '0' to 3/16" and the bevel angle can be from 40-55°. That is for SMAW with a double bevel.

P.S. Al, that joint configuration was standard widespread @ EB for CJP's of that sort double bevel groove.

P.S. Al, that joint configuration was standard widespread @ EB for CJP's of that sort double bevel groove. Most if not all shipyards use the same configuration for that type of joint also

Most if not all shipyards use the same configuration for that type of joint also