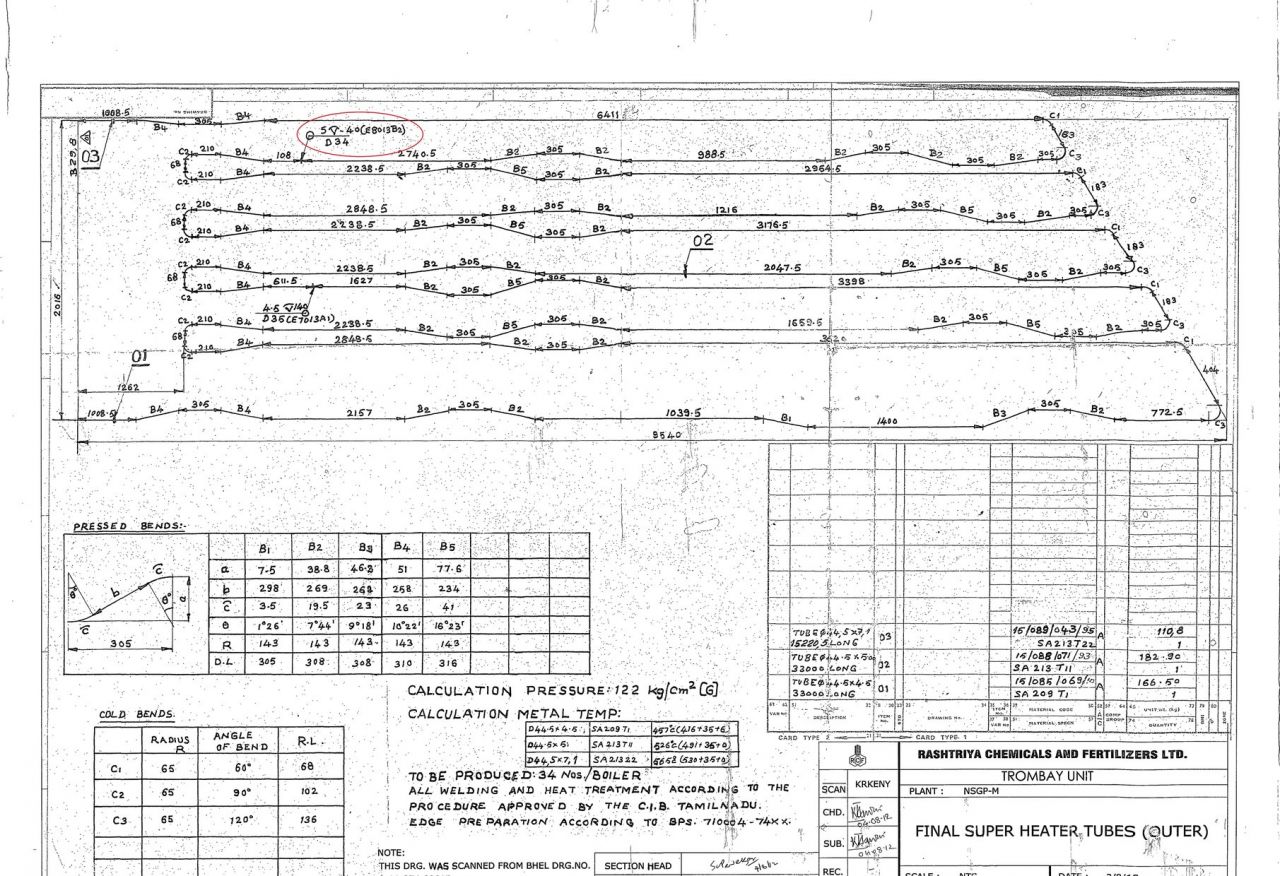

A all around V-Groove weld symbol with convex weld surface. Tail section provide info about required welding rod as E8013-B2 and now a days we mainly use low-hydrogen rods for welding Cr-Mo Steel, so you should use E8018-B2 for Stick or use ER80S-B2 with TIG. Very old outdated drawing but thanks for sharing it.

The ultimate aim is to produce a quality weld and as long as you follow the best practices such as good weld preparation, root gap welded with TIG to create a good root fusion, there is no issue at all. As a Cr-Mo steel, you have to do the PWHT of this joint.

The weld-all-around symbol or also called Peripheral weld is used to represent a weld that encircles a group of interconnected joints. In simple weld, a Weld around Symbol shows a weld that is made all around the weld location. This symbol is in the form of a circle placed at the intersection of the arrow and reference lines.

Reference: https://learnweldingsymbols.com/weld-all-around-symbol/