I went back to my post and made a correction that might make more sense.

The number of material specifications published by ASTM, API, AA, CDA, NDI, AISI, AMS can make anyone dizzy. Trying to compare one to the other is a near impossible task because, an in the case of steels, even when the chemistry is similar, the method of manufacture and final heat treatment can dramatically affect the mechanical properties. The Unified Numbering System developed by AISI and SAE does a good job of comparing the chemistries and grouping the materials into groupings that are the same or similar, but chemistry is the only consideration.

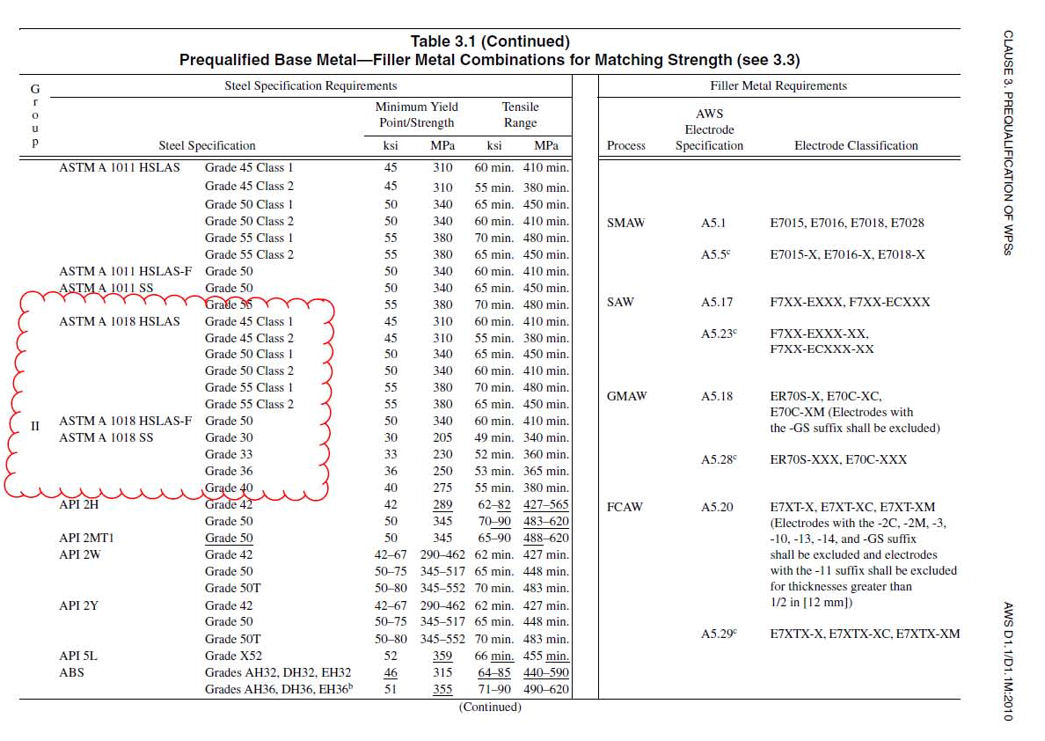

Some welding standards list the different materials by groups with similar weldability. AWS D1.1 groups the carbon and high strength low alloy steels primarily by their carbon equivalency, which is a pretty good index of their weldability when considering steels typically used for steel construction. ASME and AWS B2.1 do the same for the steels and they parallel each other, with B2.1 including some additional materials no normally encountered in pressure vessels or pressure piping.

I do not have a copy of B2.1 with me while I'm on the road, but I seem to recollect a clause that says something to the effect that if the user can find a listed materials, i.e., M-number, with a chemistry similar to the material in question, the unlisted material can by "assigned" the same M-number as the listed material. The question becomes one of how closely matched do the chemistries have to be in order to be included in a specific M-number group. I guess that is where there has to be a meeting of the minds between the purchaser and the manufacturer. I can envision conflicts of opinion when the listed material and the unlisted materials are sufficiently close enough to be considered "the same." The argument completely ignores the influence of the state of heat treatment. Consider the weldability of an AISI 1045 steel in the annealed condition versus the same steel in the quenched and tempered condition. The same can be said when working with PH stainless steels. They may be weldable in the annealed conditions and nearly impossible to weld in the quenched and precipitation hardened condition.

Best regards - Al

Al,

In your first reply this morning, you were mentioning A106 pipe, which may be causing some confusion.

The material I was having problems identifying is A108 and A576 Bar.

AS Brent mentioned, it is listed in B2.1 as ASTM ( base metal spec) A108, (Type, grade or alloy designation) Grade 1018 CW.

I know what you mean about all the separate organizations designation numbers causing dizziness. It's interesting that both the material grades I mentiond above have the same UNS number - G10180.

I seem to remember several years ago that a co-worker had a master catalog of sorts used for cross referencing various manufacturers designations to UNS numbers. I wish I had a copy of that. If anyone out there is familiar with this book and knows where I can get my hands on one, please let me know.