And let's not forget about Russell P. Meredith, Frank Pila, Peter Scheller, Eugene Gorman...

Author: Jerry Uttrachi

(President of WA Technology)

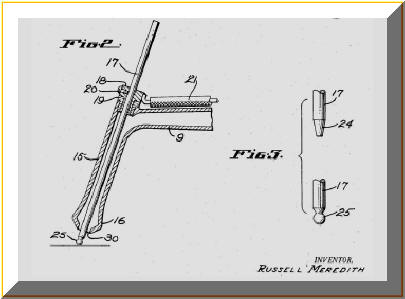

Meredith Invents TIG:

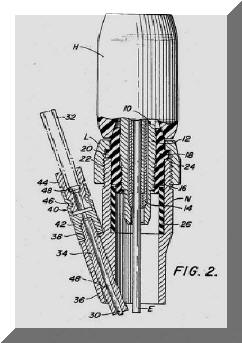

Like MIG welding, there are a number of references sighting "inventors” of TIG welding. However Russell Meredith, working for Northrop Aircraft, was the first to produce a system that was a true production tool applying for a patent in January 1941 (US Patent # 2,274,631, Figure below.) He was concerned about meeting a critical national need of welding light weight aircraft materials. In the first line of the patent it states; “My invention relates to welding magnesium and its alloys - - so relatively low melting point materials may be efficiently welded by an electric arc.” He goes on to say that airplanes are being made of lighter materials and a more efficient method of joining these materials is needed.

Although Meredith's work was done with Helium shielding gas and a tungsten electrode his 4 patent claims are very broad only mentioning an "inert gas" and “refractory” welding electrode. Validating that this was the first workable system and Meredith was the inventor of TIG; there is no prior art sited against his patent by himself or the US Patent Office.

Similar to the 1st MIG Welding Patent emphasizing the need for Laminar shielding gas flow, Meredith states that the shape of the end of his TIG torch is designed to prevent oxygen (referring to air intrusion) from being drawn into the arc by the Helium outflow. From a review of other devices shown in prior patents it is obvious the inventors did not understand the importance of shielding quality and what was required to produce Laminar flow. Note: I encourage reviewing these patents, which is a reason the numbers are provided. There is a great deal of useful information available - and they are Free! (Unfortunately some of today's welding professionals do not understand that excess gas flow creates turbulence that pulls air into the shielding stream. Depending the nozzle size, the flow rate causing turbulence is only somewhat higher than that used when welding! )

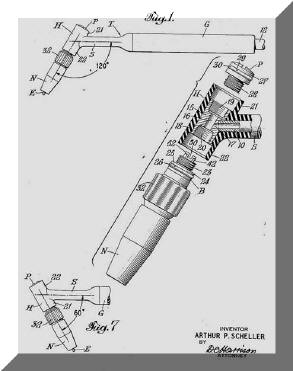

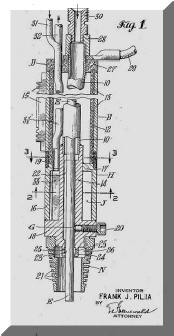

Linde Buys Patents and Heliarc Name:

Meredith and Northrop Aircraft called the welding process HeliarcR and sold the patent and trademark rights to the Linde Division of UCC. Linde, unlike Northrop, had the incentive to spend the needed funds and manpower to develop the process since their business was manufacturing and marketing inert (and other industrial) gases. They developed a whole series of Heliarc brand torches. Frank Pilia who worked in the Linde Labs invented and patented a water cooled TIG torch (# 2,468,806 filed May, 1946; figure below.) Pete Scheller also worked for Linde and filed a patent in May 1951, # 2,685,631, for a torch where the head could be bent as needed for access to difficult to reach areas such as pipe welding (figure below.)

Some two decades after these early inventions, I worked on various projects at the Linde Labs with Frank Pilia and Pete Scheller who were very creative engineers. One, which I developed and patented, a High Speed Electroslag system, Pete Scheller designed the mechanical tractor device. Note, Linde (now renamed Praxair) sold their welding equipment and filler metal business in the 1980's and the Heliarc Brand products are now owned and marketed by ESAB.]

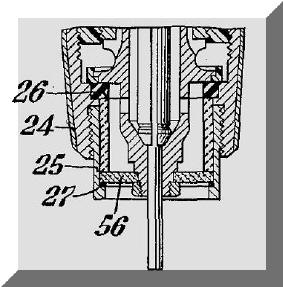

In addition to numerous torch patents, Linde developed systems to improve shielding and allow the tungsten electrode to protrude further from the gas cup for better visibility while still providing the needed excellent shielding. Another colleague, Gene Gorman, invented the first “gas lens” as it was referred to in his patent filed April 1960, US 3,053,968. Item # 56 (below) shown in patent figure upper left is referred to as a “baffle” with a varying number of holes. As Gorman notes in the patent teaching, very small holes produced a longer coherent gas stream substantially without Turbulence. One material mentioned was a 200 mesh screen. This produced much better shielding than the porous bronze type materials he evaluated. When Gorman tested porous bronze materials he found the gas leaving this type of materials exited in various directions creating a more Turbulent gas stream!

Some companies are trying to sell porous material designs for a gas lens-it is no doubt much easier to make! Wonder if they ran the Schlieren gas flow tests and made sufficient welds in various materials to validate its effectiveness, as did Gorman? See Gas Lens Tests Below. I shared an office with Gene when I started at the Linde Labs. Gene was developing a three electrode TIG system for high speed welding of stainless steel in tube mills. I was developing a three wire Submerged Arc System that welded large diameter UOE steel pipe for oil and natural gas transmission, which welded with 3000 amps!]

Gorman shows the resulting gas outflow in one of the patent figures (below) and quantifies his finding in a graph. The graph (below) shows an improvement in the length of the coherent gas stream of 6 fold with a device he called a gas lens.

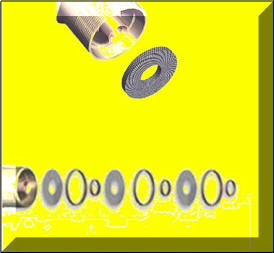

Another Linde engineer, Cliff Hill, defined an improved method of making a gas lens in his patent filed in 1961, # 3,180,967. Cliff’s design (patent figure below) used multiple fine size screens stacked to provide the Laminar flow needed and as defined in the Gorman patent. He found these very fine screens could be combined with a coarser, more ridged screen on the outside to improve the durability of the assembly. This construction did not alter the ability to produce the desired long coherent gas stream. This design is still used today to produce the best quality shielding gas lens..

Cliff Hill was a very dedicated engineer with many patents in the TIG torch area. He was a very creative person and a man of few words. I recall a comment made by Cliff after a lengthy meeting we were having with engineering. He said, "perhaps we should remove all the chairs in this conference room and the meetings won't last as long!"

Gas Lens Test

Engineers at ESAB recently tested several TIG gas lens designs after reviewing problems encountered by a major shipyard. One type was a single piece made of a porous material and the other had multiple screens similar the genuine Heliarc design that ESAB markets but with fewer and coarser screens.

The most definitive test results were observed after carefully making welds with AC power in aluminum and noting the quality of the cleaning action. The amount and consistency of cleaning with the porous, single piece material and the one with coarse screens was not much better than welds made with a standard non-gas lens collet. The genuine Heliarc Gas lens with fine internal screens and a coarser cover screen, as originally patented by Hill (see below,) gave excellent uniform cleaning, much better than the other two types.

Gorman in his tests in the early 1960's reported in his initial patent (see below) explaining why he found porous materials did not work - the gas exits in various directions. He discovered stacked fine screens provided the desired long, laminar gas stream.

Pressed porous materials and the use of fewer, lower cost, coarse screens are no-doubt much easier to produce and lower in cost than the properly assembled, more expensive fine screen design. However the weld results showed this was false economy!

The gas lens allows the tungsten to be placed well outside the gas cup to increase visibility (the actual gas flow with and without a gas lens is shown below).

TIG Hot Wire

The TIG welding process saw a major advancement when an engineer at the Linde Labs invented TIG “Hot Wire.” Gus Manz filed patent, 3,122,629 in February 1962. It provided TIG quality with MIG deposition rates. It was mostly (and still is) used for automatic installations.

Instead of slowing adding cold wire to the TIG weld puddle, the “Hot Wire” is heated just below the melting point and reacts just like squirting toothpaste into the puddle! The wire exits the contact tip cold (T in the above schematic) and is heated by a power source (H) as it passes from the tip to the weld puddle with just enough power to make it "mushy" as it enters! MIG metal deposition rates are achievable. A subtle but important advantage is the heated wire burns off all volatile wire surface residuals before it enters the puddle making it an extremely low hydrogen process.

Another colleague, Fritz Saenger, in patent 3,588,464 filed in April 1969, defined a potentially very useful product, a manual TIG hot wire torch. This torch design made it easy for a welder to add the “Hot Wire.” It takes this integrated approach to achieve a system that will work in production better than simple add-on approaches.

Other TIG Innovations:

There were other innovations such as very high frequency power that constricts the arc and multi-electrode systems that increased speeds in production such as welding on stainless tube mills. Flexible and silicon covered TIG torches were also introduced. Today’s microprocessor controlled inverter power systems also make TIG welding easier to use and more controllable.

Note: Heliarc is a registered trademark of ESAB Welding & Cutting.

Capabilities and Background

Overview of Welding Consulting Capabilities:

Jerry Uttrachi, President WA Technology, LLC

Email: Jerry_Uttrachi@NetWelding.com

Capabilities: Assistance with reduction in shielding gas waste. Training welders and supervisors on the technical aspects of shielding gas control. Welding process and consumable assessment, selection and automation. Welding process training. Extensive practical experience increasing welding productivity and submerged arc welding in pipe production.

Academic Background/Affiliations: Mr. Uttrachi has a Bachelors and Masters Degree in Mechanical Engineering and a Master of Science Degree in Management from New Jersey Institute of Technology (NJIT). He is a member of ASME and AWS. He was selected as an AWS Counselor for his leadership and training efforts. The citation for that award included the following wording; "- - he has trained a whole generation of salesman, end users and distributors in a wide variety of welding processes and equipment through personnel training and development of training materials."

Mr. Uttrachi was inaugurated as 2007 President of the American Welding Society at their annual Exhibition in Atlanta Georgia. The photo left was taken at that ceremony with his "classmate," Harry Ebert (left in photo; who before retiring was chief welding engineer for Exxon) graduated as a Welding Engineer in 1948 then he and Mr. Uttrachi (center) obtained Masters Degree in the Behavior of Metals at NJIT in the late 1960's. Gus Manz (right), also an NJIT graduate, has numerous patents in the welding field related to the early power supplies for MIG welding and was the inventor of "Hot Wire TIG and MIG Processes." Gus was a colleague at the Linde Development Laboratories.

Mr. Uttrachi has been a Trustee of the AWS Foundation for the past 12 years and is currently Chairman of the Board of Trustees. He has served on numerous AWS committees including Filler Metals Committees, Technical Papers Committee, Handbook Committees, Marketing, Exhibition & Publication Committee which he chaired for 9 years, New Product Development and the Membership Committee. He currently is a member of the Metric Practice Committee, Intellectual Property Committee and Conference Committee. He is also a member of the American Society of Mechanical Engineers and serves as Chairman of his local Section.

Welding Industry Experience: During his 40+ year career in the welding industry, Mr. Uttrachi has managed a welding shielding gas and filler metals Development Laboratory for the Linde Division of UCC (now Praxair) and was Vice President of Marketing for L-TEC Welding & Cutting Systems and subsequently ESAB Welding Products. He is responsible for a number of developments in welding shielding gases, filler metals, equipment and welding processes and was granted a number of related patents. Some of his work has been published in technical journals and trade publications including the AWS Welding Journal.

Patents: He holds a number of United States and foreign patents in the welding process, welding equipment and filler materials areas including five recent patents including four concerning weld shielding gas conservation and weld quality improvement:

1. Patent # 3,659,073;” Method of DC Constant Potential Submerged Arc Welding”

2. Patent # 3,778,587; “Flux Cored Wire With 200 to 2000 ppm Oxygen”

3. Patent # 3,854,028; “High Speed Electroslag Welding”

4. Patent # 4,256,949; “Method For Submerged Arc Welding Of Pipe”

5. Patent # 4,645,903; “Gas Metal Arc Welding (MIG) Process”

6. Patent # 6,610,957;”Welding Shielding Gas Saver Device”

7. Patent # 7,015,412; "Welding Shielding Gas Saver Flow-Control Device"

8. Patent # 7,019,248; "Welding Shielding Gas Flow Control Device"

9. Patent # 7,462,799; "Welding Shielding Gas Flow Rate-Limiting Apparatus"

10. Patent # 8,104,094; "Clean, Cool, Comfortable Welding Helmet"

Publications:

Published in The AWS Welding Journal:

1. “Three-Wire Submerged Arc Welding of Line Pipe”; (See recent summary)

2. “A New DC Power System for Submerged Arc Welding”;

3. “Electroslag Welding Speeds the Making of Ships”;

4. “Multiple Electrode Systems for Submerged Arc Welding” (See recent summary)

5. “Basics of Semiautomatic (MIG) Welding.”

6. "NASCAR Race Team Demands Quality Welds.” (See Article; includes 4130) Also see "Welding 4130" or "Welding Race Cars" on this site.

7. "GMAW Shielding Gas Flow Control Systems." (See Article)

8. "Those Were The Days: The 1980's Decade of Change

Welding Design & Fabrication:

9. “Selection of Submerged Arc Wire and Flux,”

10. "What Do Robots Need in Welding Equipment,"

11. Interview, “Bridge Welding Global Style,"

Trailer Body Builders Magazine

12. "Solution to Weld Shielding Gas Waste." (See Article in Magazine)

13. "Texas Fabricator Reduces MIG Welding Shielding Gas Waste." (See Article in Magazine)

American Institute of Steel Construction

14. "Innovations in Welding and Cutting." AISC 1997 Conference Proceedings

Tube and Pipe Association / FMA

15. "Managing GMAW Shielding Gas Flow " 2005 Pipe Fabricating Conference Proceedings

Welding in the World (IIW)

16. "Gas Waste and Weld Start Quality Issues in Common GMAW Shielding Gas Delivery Systems and Suggested Solution"

Production Experience: Mr. Uttrachi has worked with a number of industries in defining methods and approaches for solving welding problems. The welding process developed for submerged arc welding of pipe has been installed in a number of countries around the world including; USA, Mexico, South America, Middle East, Japan, UK, and Italy. The system is capable of producing high quality, high speed welds without interference from defects caused by arc blow.

http://www.netwelding.com/History_TIG_Welding.htmhttp://www.netwelding.com/capabilities_and_background.htmRespectfully,

Henry

I got his number long ago ......Just never called him out on his B.S. (bet he can't even throw a code weld) glad somebody finally called him out......

I got his number long ago ......Just never called him out on his B.S. (bet he can't even throw a code weld) glad somebody finally called him out......

( hate a guy that talks religon but screws anybody that falls for his STORY)

( hate a guy that talks religon but screws anybody that falls for his STORY)

By the way up in the northeast "heli-arc" has held on forever...even have had "engineers" call and inquire on it's availability and still see it in job specs. for aluminum rail

By the way up in the northeast "heli-arc" has held on forever...even have had "engineers" call and inquire on it's availability and still see it in job specs. for aluminum rail