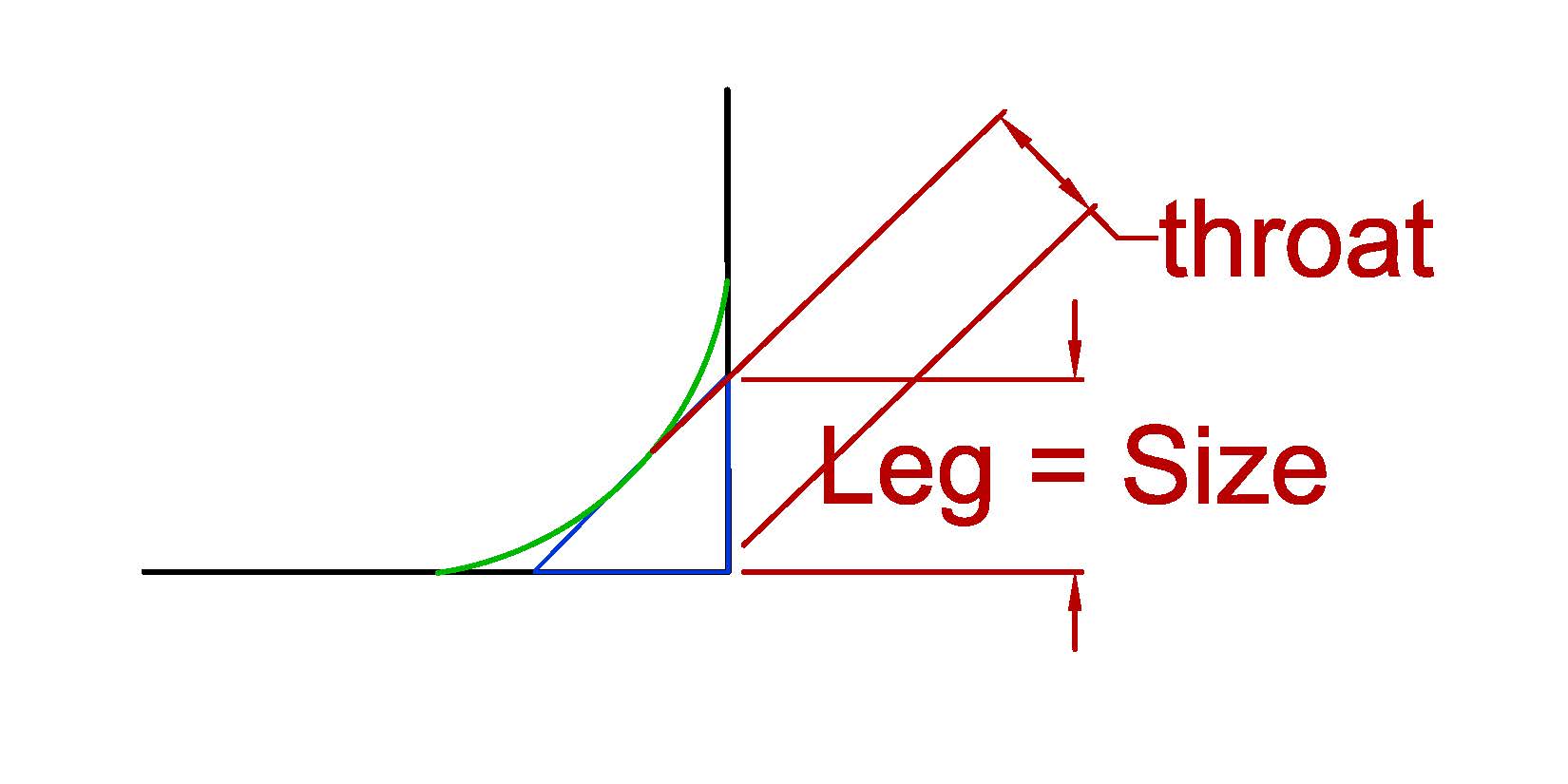

NO!! The 'wash' is NOT part of the legitimate measurement of the leg. If that were so I could make a 1/2" fillet out of a 5/16" when it is 'washed' up the side further even though it adds absolutely NO strength to the weld or length to the true leg.

So, with that in mind, I must respectfully disagree with the illustration as presented on using the fillet weld gauge. The only way that that gauge, which is a 'go-no go' gauge, can tell you the leg is long enough is when there is an ever so slight gap because the leg at the toe is slightly preventing the gauge from contacting the vertical member. Otherwise it is a matter of opinion if that weld is large enough especially if one is looking at the 'wash' and says, 'yes, there is weld under the gauge so the leg is long enough'.

Or, I could even grap the next size larger gauge and say, yes, its close enough or the wash is under the point of the gauge, that's a 5/16" fillet.

If there is not a gap between the face of the vertical member, it isn't the proper size. Totally speculative and open to personal judgement call. That isn't how it should be done.

Someone is going to say, but you are allowed to be undersized. Yes, but only for a short amount of distance. The rest must be the correct size.

I will add a couple of pics to show my perspective. While looking at the pics, if you were to push the gauge on up so that the face of the gauge touches the vertical member, then you could see a slight gap on the bottom surface of the gauge. There will be a gap between one or the other. If not, I could make a lot of things pass for a size that they are not.

He Is In Control, Have a Great Day, Brent